Custom programming :

In a glass hot-forming application, the difficulty lies in describing the process as a formal sequence of operations. The glassworker’s manual work requires skill and experience. Any automatic machine, no matter how sophisticated, will require instructions to operate.

To solve this problem, Verresatine uses a unique programming tool, specific to each of your creations. With potentiometers and buttons, our glassblower creates a reference piece on the automatic lathe. During this operation, which is called Acquisition, the machine records all of the actions carried out by the glassblower (movements of tools, burners, tailstock, lathe spindle speed, gas flow, blowing pressure, and also thermographic and dimensional data).

Once acquisition is complete, our software analyses all of the information recorded during the process. It finds correlations between the actions of the glassblower and the technical information collected to create your production programme. This compilation phase is called Conversion. In practice, it means that our machine has learned the glassblower’s actions, but also the conditions under which the actions must be performed.

In the third and final step, the programme is executed and the automatic process is analysed by our glassblower. Finally, corrections can be made directly in the programme to improve the quality or speed of production. This step is called Fine-tuning.

This programming method provides very good results in a short amount of time; typically a few hours for one application.

Flawless adaptability :

When a glassblower works on a manual lathe, he works in a closed loop. He performs an action, checks the impact on the glass, and then decides on his next action. The effect analysed may be related to the viscosity of the glass (temperature) or its shape (dimensions).

This method allows the blower to adapt to variations in the work environment in order to reproduce the same final result.

Our lathe operates according to the same principle. The thermographic camera continuously measures the temperature profile and the dimensions of the glass. The lathe then works at the defined locations according to the results of these measurements. As the machine is able to perform these measurements with much greater accuracy than a glassblower, the final result is also more precise and repetitive.

We can therefore achieve tolerance values around ± 0.05 mm.

Another impressive characteristic of our equipment is the time it takes to switch from one production to another. In practice, it does not take more than 10 to 15 minutes to modify production, which makes our equipment flexible and profitable, even for small production campaigns.

The Verresatine teams pay extra close attention to detail and machine finishing of pieces.

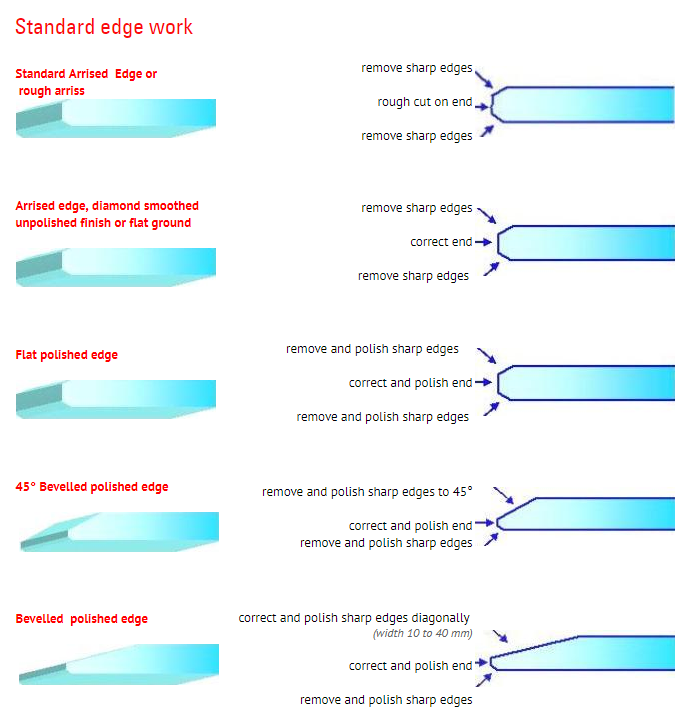

Cold working is surface treatment of glass pieces, without deforming the mass of the glass, most often consisting in the removal of material.

This step includes cutting and rework operations as well as finishing. These operations allow us to modify the surface of the piece to eliminate imperfections that may have been left by hot working (mould seams, folds, etc.).

A FEW OF OUR AREAS OF EXPERTISE:

• WATERJET CUTTING:

Waterjet cutting technology is a very effective machining method for glass. It allows us to make lines and shapes that would be impossible with other traditional cutting machines. It therefore provides the possibility to make very thin and complex profiles, without cracking the glass or requiring edge grinding.

• DIGITAL PRINTING AND SCREENPRINTING ON GLASS:

Digital printing on glass is a process that applies a permanent, high-quality image on a piece of glass. We can use this process to print all kinds of 4-colour images using a white backing.